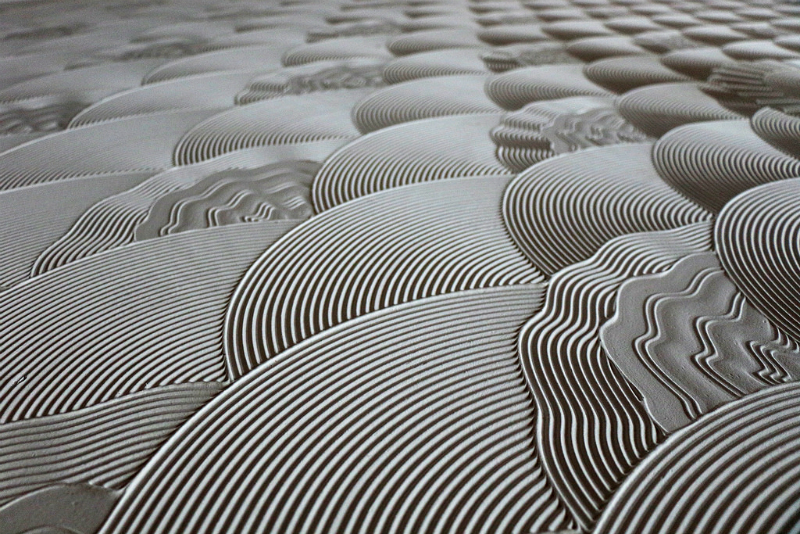

Artex is a trade name commonly used to describe textured decorative wall coatings. It is typically found on walls and ceilings and may have various patterned effects including stippling, swirls, patterns or a smooth surface.

Textured Coating became popular in the 1960’s and is found mostly in properties built in the 70’s and 80’s. For many years, Artex was mainly manufactured using chrysotile (white) asbestos cement mineral fibres which are often referred to as ‘white’ asbestos.

It is believed that there around 50% of UK households with asbestos-containing wall coverings within them.

Artex was historically manufactured using asbestos to strengthen the mix and prevent cracking during drying. Although textured wall coatings are less popular today, older ceilings may still contain white asbestos fibres which are potentially hazardous to health.

Is Artex Dangerous?

Undisturbed and in good condition, Artex posses little to no risk to human health.

However, when scraped, broken or drilled, potentially harmful asbestos fibres contained within the artex can be released into the surrounding atmosphere.

It is therefore important that homeowners check to ensure that the Artex on their ceilings does not contain the product before they attempt to remove or scrape it.

How do I tell if artex contains asbestos?

To confirm if a textured coating contains asbestos an asbestos test should completed. We recommend that two samples are taken as a precaution as uneven application can produce negative results. The sample is sent to an independent lab for testing.

Not all textured coating contains asbestos. Taking a sample will also confirm if no asbestos is present.

Never drill, scrape or sand artex ceilings unless you are absolutely certain no asbestos is present.

How is the asbestos in Artex disturbed?

Asbestos in textured coatings is disturbed when any activity which can damage the material is carried out, such as drilling, hammering, carrying our refurbishment works or replastering. You should not scrape or sand a stippled coating to ‘skim’ over it with plaster unless you are carrying out the activity in a controlled manner following HSE guidelines as this may result in asbestos fibres becoming airborne.

Artex may also be disturbed if their is a floor damage such as a water leak in a loft area or roof. This may make the ceiling unstable and more liable to cracking.

How much chrysotile asbestos was contained in Artex?

There were two types of Artex containing asbestos sold – a ‘trade’ and ‘retail’ version. The final asbestos content can vary and the HSE say:

“Typically the dry powdered mix for trade use Artex contained about 3.8% w/w of chrysotile asbestos and the ready mixed DIY product (known as W14) contained somewhat less – 1.8% – and an emulsion binder. According to the manufacturer asbestos was added only to promote the dewatering and curing of the product, but the asbestos fibres will have a reinforcing effect on the matrix.” (HSE Watch Committee Paper – WATCH/2006 /1).

How To Get Rid Of Artex Ceilings

Although the removal of asbestos-containing textured coatings is classed as non-licensed work, steps must be taken “to prevent or reduce the spread of asbestos” under the Control of Asbestos Regulations (CAR). In addition, CAR states that the work should “only be carried out by trained and competent staff, using appropriate control measures.”

Removing Artex can create a lot of dust and debris which in turn may contain asbestos fibres. Asbestos fibres are not visible to the naked eye but can be damaging to human health if inhaled or ingested and can lead to fatal lung diseases or cancers such as mesothelioma. Removal of textured decorative coatings is best carried out by a HSE licensed asbestos removal contractor who will have the knowledge, skills and specialist equipment required to carry out the work safely and effectively. HSE contractors also carry specialist insurance to cover working with asbestos.

Ashbee Solutions Limited ensure that the area is correctly protected with polythene sheeting (such as windows, cupboard, sink, floor, wall) and all dust residue is removed. Removal always takes place under controlled conditions using a negative pressure unit and includes the construction of a temporary airlock. The area is cleaned using HVAC vacuum cleaners. Background air testing for reassurance and reoccupation can also be provided on request from the customer.

Artex on Plasterboard

When applied to plasterboard, the only way to ensure complete eradication of the asbestos containing artex is to have the entire ceiling (including plasterboard) removed. It will then be necessary for a builder or plasterer to replace the ceilings and plaster, if required.

Artex On Lathe and Plaster

Artex applied to lath and plaster can be very messy to remove and creates a lot of dirt and dust. As with the plasterboard removal methods, all of the material is removed and requires new plasterboard ceilings to be installed once the asbestos is removed.

Artex on Concrete

Artex applied to concrete is usually removed using a special chemical, along with a hand-scraping technique.

What is a Negative Pressure Unit (NPU)?

An NPU is a specialist piece of equipment used by HSE licensed asbestos removal contractors to produce a negative pressure environment (vacuum) in an area to prevent the egress of asbestos fibres into the outside area. At the same time, any fibres which may be released during the removal process are caught in a special HEPA filter.

You should make sure that any company removing textured decorative wall coatings from your property use this equipment as a failure to do so may result in asbestos contamination spreading throughout your home.

| Shopping around for quotations? Please ensure that quotations include the price of removing the coatings under semi-controlled conditions. This means that the removal company should use a negative pressure unit (NPU) to suppress dust and prevent asbestos fibres spreading through the building. |